Vitrification as an ultrarapid cooling technique is based on direct contact between the vitrification solution containing the cryoprotectant agents and the liquid nitrogen ln 2.

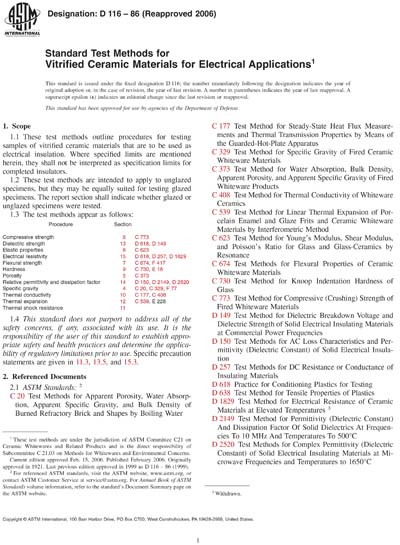

Vitrification ceramics pdf.

The vitrification and crystallization techniques yield dense glasses and glass ceramics respectively.

Basudeb karmakar in functional glasses and glass ceramics 2017.

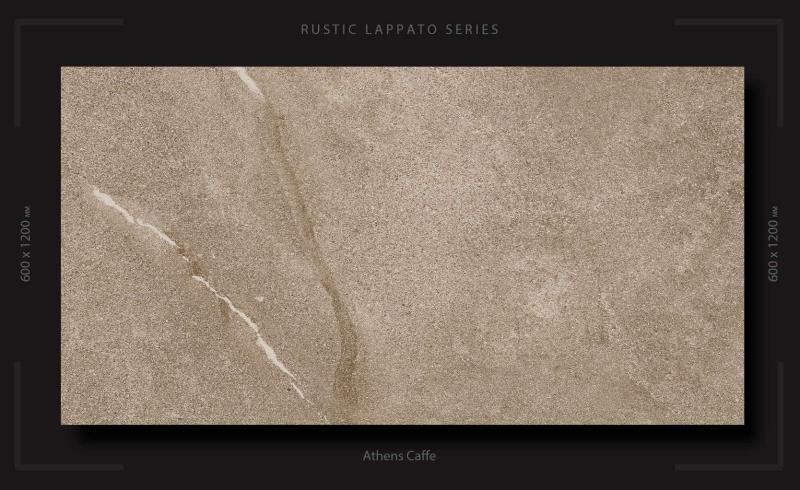

In the production of ceramics vitrification is responsible for its impermeability to water.

Vitrification from latin vitreum glass via french vitrifier is the transformation of a substance into a glass that is to say a non crystalline amorphous solid in the production of ceramics vitrification is responsible for its impermeability to water.

The protocols for vitrification are very simple and they allow cells and tissue to be placed directly into the cryoprotectant and then plunged directly into ln 2.

The ultimate purpose of firing is to achieve some measure of bonding of the particles for strength and consolidation or reduction in porosity e g for impermeability to fluids in silicate based ceramics bonding and consolidation are accomplished by partial vitrification vitrification is the formation of glass accomplished in this case through the melting of crystalline.

Average diminishing factors k w for the vitrified aqueous radioactive waste see section 3 6 are of the order of 10 4 10 5 sufficient to provide safe long term storage of hlw in above ground facilities as well as safe transportation and final disposal.

Vitrification is usually achieved by heating materials until they liquidize then cooling the liquid often rapidly so that it.

These are the well established techniques for converting various kinds of solid wastes into several reusable materials with excellent chemical stability 1 3 5.

Vitrification is usually achieved by heating materials until they liquidize then cooling the liquid often rapidly so that it passes.

.jpg)