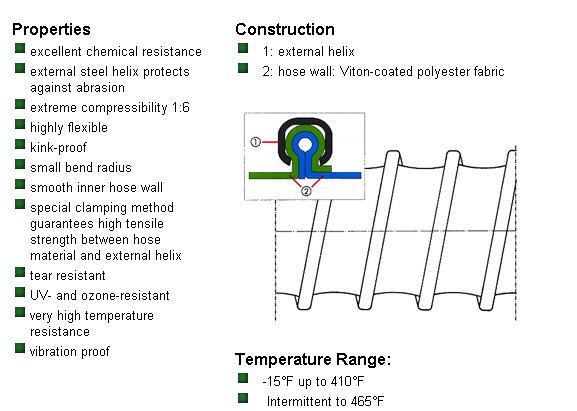

Many expansion joints work in harsh environments that might include excessive pressure and temperature or exposure to corrosive chemicals and the elements.

Viton fluoroelastomer rubber properties.

Makes no expressed or implied warranty as to any qualities attributes or.

While viton can be sometimes distinguished from other types of rubber by its often green or brown colour a more reliable test is its density of over 1800 kg m 3 significantly higher than most types of rubber 1010 1520 kg m 3.

Their durability and reliability ensures higher performance less downtime and a competitive advantage for designers and engineers using viton fluoroelastomer products.

Robinson rubber products company inc.

Fkm viton viton is a registered trademark for fluroelastomer by dupont performance elastomers l l c.

While expansion joints can be made from many types of rubber those made with viton high performance fluoroelastomers can be designed for the most demanding applications.

This fluoroelastomer fkm viton was introduced in 1957 to meet the requirements in the aerospace industry for a high performance elastomer.

The properties and characteristics of manufactured rubber products may vary based on polymer type and formulation.

Products made with viton fluoroelastomers retain their flexibility shape and seal when exposed to chemicals and high temperatures.

Formulate a fluorocarbon fluoroelastomer rubber compound to meet your specific application and performance requirements please contact robinson rubber products at e mail.

Our rubber products are a proprietary blend of various polymers formulated to meet stated physicals and specifications.

Specific gasket sheet properties should be taken into account before use in the gas and oil industry.

Following its introduction the usage of viton spread quickly to other industries including the automotive appliance chemical and fluid power industries thanks to its natural.

Trade names include fluorel viton and technoflon.

Please note that information presented here is general to fluoroelastomer polymer.

One of the special grades we refer to on our site is viton extreme etp 600s.

The fluorine content of the most common viton grades varies between 66 and 70.

Viton freeflow extrusion process aids also improve processing increase output and reduce waste.

Viton rubber a specific fluoroelastomer polymer fkm was introduced into the aerospace industry in 1957 to fulfill its needs for a high performance elastomer.